Project Description

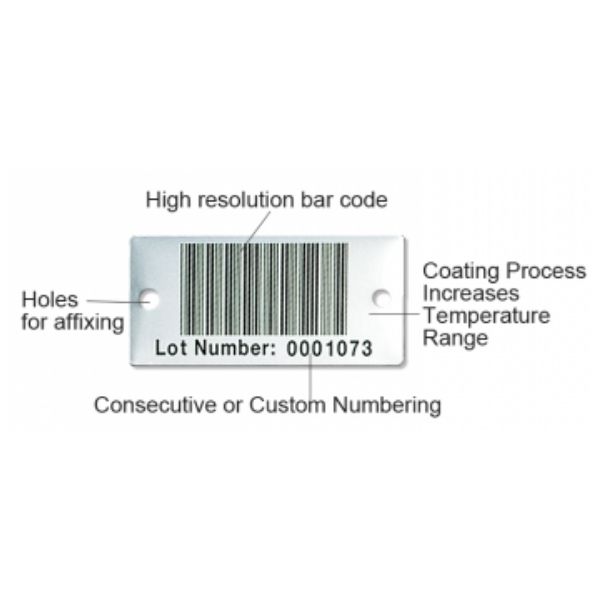

Made of durable anodized aluminum, idtracon’s High Temperature Metal Barcode Tags are ideal for applications with temperature requirements from 482°C-650°C.

In addition, these tags have many of the same benefits that our standard metal barcode tags-including an image that is sealed within the anodic layer of the aluminum protecting it from abrasion, solvents, and chemicals.

Unique coating process that increases temperature range to 650°C

Photographically reproduced black copy, logos, and bar codes ensure accurate and reliable reads

Anodizing process protects black copy, logos, and bar codes from chemicals, abrasion, and high temperatures

Specifications Data

| Material | .008” thick matte anodized aluminum is standard. Optional thicknesses include: .012”, .020”, and .032”. |

| Serialization | All alphanumeric bar codes are photo imaged with a human-readable equivalent. Guaranteed no skips in sequence. Code 39 with 2.7 to 9.4 characters per inch (CPI) is standard. Other bar code symbologies including Code 128, I 2 of 5, 2D DataMatrix and QR Code. OCR characters and CPIs also available. |

| Label Copy | The printed nameplate copy is block type only. No stylized type, logos or other designs available. All copy is photo imaged. |

| Colors | Available in black only |

| Sizes | Various sizes available |

| Holes | Optional |

| Packaging | Shipped in “work-out-of” cartons for convenient application. Each carton consists of one or more plastic trays containing 250 sequentially packed nameplates (can vary with metal thickness). Both cartons and trays are clearly marked to indicate serial numbers of contents. |

| Shipment | 20-25 business days |

High Temperature

OEM Product Identification

Work-In-Process

Chemical Test Data

| Characteristics | Test conditions | Effect |

| Water/humidity | no effect | |

| Salt spray | 5% at 35°C, 700 hours | no effect |

| Ammonium hydroxide | 2 hours at 1% and 5% | Slight dulling of image, affects overall readability |

| Ethyl alcohol | 72 hour immersion | no effect |

| Ethyl acetate | 24 hour immersion | no effect |

| Ferric chloride | 10%, 16 hours | no effect |

| Heptane | 72 hours | no effect |

| Hydrocarbon fluid | 1 hour immersion | no effect |

| JP-4 fuel | 72 hour immersion | no effect |

| Kerosene | 12 hour immersion | no effect |

| Methyl ethyl ketone | 24 hour immersion | no effect |

| Nitric acid | 1%, 40 hours | no effect |

| Phosphoric acid | 1%, 12 hours | no effect |

| Skydrol | 24 hr immersion (room temp & boiling) | no effect |

| Sodium hydroxide | 1%, 1 hour | affects overall readability |

| Sulfuric acid | 10%, 24 hours | no effect |

| Turbine and jet fuel (MIL-L 5161C) | (MIL-L 5161C) | no effect |

| Tetra Sodium Pyrophosphate | 1%, 40 hours | no effect |

| Trisodium Phosphate | 1%, 40 hours | no effect |

Destructive Test Data

| Image Intensified | Weatherometer, 20 years equivalent | Reduced overall readability after these thresholds |

Temperature Test Data

| Image Intensified | 168 hours at 538°C; max temp 650°C | Reduced overall readability after these thresholds |

Abrasion Test Summary

| Image Intensified | Plates brushed for 7,000 cycles with stiff nylon wheel (C-17) at a 1,000 gm (16 ox.) load | Reduced overall readability after these thresholds |