Project Description

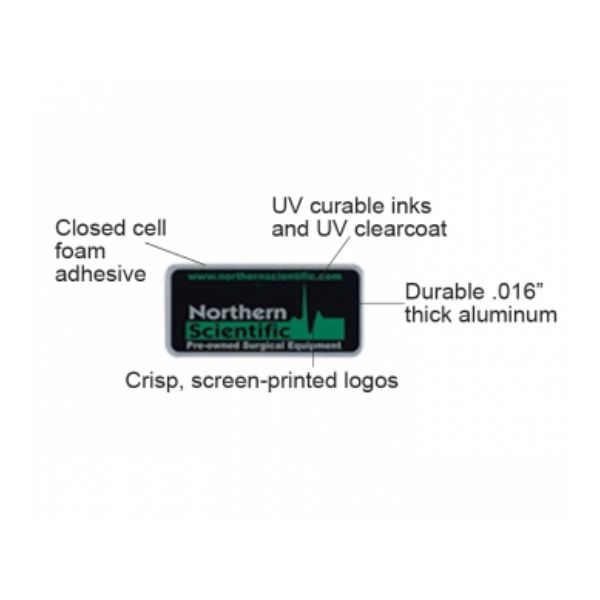

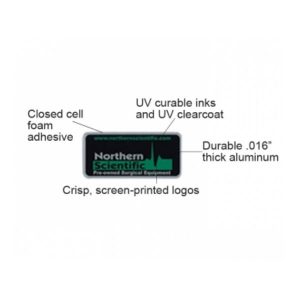

These .016” thick aluminum nameplate offer the greatest flexibility in nameplate design.

AUTOGRAPHS® Nameplates feature UV curable inks and a clear coat that protects against damaging UV rays while screen printing maximizes registration accuracy and resolution allowing for clear, crisp reproduction of company logos and designs.

UV curable inks and UV clear coat provide protection against damaging UV rays

Optional indented black-filled serial numbers available

.016” thick aluminum provides rigidity and durability

Adhesives specially matched to surface for maximum adhesion and/or optional holes available for mechanical fasteners

More than 700 sizes means no extra tooling charge

Break-away tab for easier liner removal available on limited sizes

Specifications Data

| Material | .016” thick anodized aluminum is standard. Optional thicknesses .020”, and .032”. |

| Serialization | Optional indented serial numbers permanently stamped into the aluminum and filled with black enamel. Additional fill colors are available. Serial numbers available in three sizes: 1/8”, 3/16” or 1/4”. Guaranteed no skips in sequence. |

| Label Copy | The printed nameplate copy may include block type, stylized type, logos or other designs. |

| Colors | Choose from our standard colors (red, yellow, blue, green, orange, white, purple, dark blue, black)). The use of one or two colors is standard. Additional color options available. Custom colors also available. Metalcraft color samples available upon request. |

| Standard Adhesive | .0031” thick, closed cell polyethylene foam adhesive that provides excellent surface area adhesion to most surfaces including irregular surfaces; optional adhesives available |

| Sizes | 51mm x 25mm, 38mm x 19mm, 63mm x 19mm, 38mm x 13mm, 76mm x 25mm, 51mm x 16mm, 51mm x 19mm |

| Holes | Optional |

| Packaging | Shipped in “work-out-of” cartons for convenient application. Each carton consists of one or more trays containing sequentially packed nameplates. Both cartons and trays are clearly marked to indicate serial numbers of contents. Pressure-sensitive adhesive orders are shipped with a roller, cleaner, and application instructions. Roller is recommended when applying nameplates. |

| Shipment | 8-10 business days |

OEM Product Identification

Product Branding

UL Approved Labeling

Work-In-Process

-

Chemical Testing

-

Temperature Testing

-

Abrasion Testing

-

Label Adhesion Testing

Chemical Test Data

This rating measures readability after being exposed to chemicals listed below for a 24-hour soak. Chemical emergence tests are rated on a scale of 100 to 0: 100 = No Effect 75 = Image blurred 50 = Image scratches off 25 =Image wipes off 0 = Image destroyed

| Test Conditions | Rating |

| Acetone | 100 |

| Isopropyl Alcohol | 100 |

| Bathroom cleaner | 80 |

| Glass cleaner | 100 |

| Sodium hydroxide | 0 |

| Hydrochloric acid | 100 |

| Nitric acid | 100 |

| Brake fluid | 100 |

| Water | 100 |

Temperature Test Data

AUTOGRAPHS® are able to withstand intermittent heat exposure to 175°C.

Abrasion Test Data

Nameplate survived more than 1,000 revolutions on Taber Abrader using Calibrase CS-10 wheel with 500g weight.

Label Adhesion Test Data

| Test Conditions | Rating |

| Acetone | 95 |

| Isopropyl Alcohol | 100 |

| Bathroom cleaner | 100 |

| Glass cleaner | 100 |

| Sodium hydroxide | 100 |

| Hydrochloric acid | 100 |

| Nitric acid | 100 |

| Brake fluid | 100 |

| Water | 100 |