Project Description

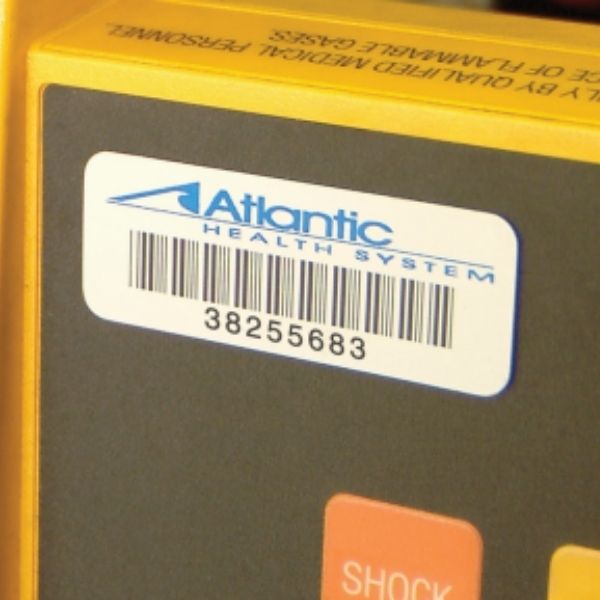

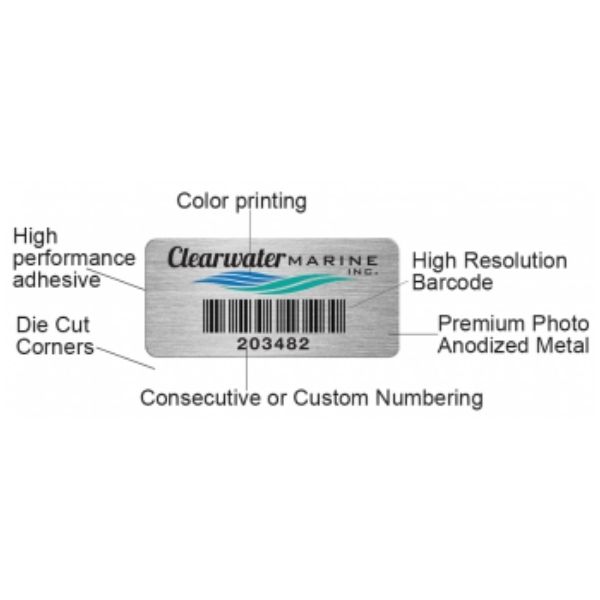

Metal Barcode Tags are ideal for customers who require permanent nameplates to stand up in harsh environments. Black copy, logos, and barcodes are photographically reproduced for maximum clarity and detail, then sealed within the anodic layer of the aluminum – ensuring accurate and reliable reads for years to come.

Photographically reproduced black copy, logos and barcodes ensure accurate and reliable reads

Anodizing process protects copy, logos and barcodes from chemicals, abrasion and high temperatures

Adhesive specially matched to surface for maximum adhesion or optional holes available for mechanical fasteners.

Optional intensification process increases heat resistance and improves the image resistance for other environmental conditions

| Material | .008” matte anodized aluminum is standard. Optional thicknesses include: .012”, .032”, and .063”. |

| Serialization | All alphanumeric barcodes are photo imaged with a human-readable equivalent. Guaranteed no skips in sequence. Code 39 with 2.7 to 9.4 characters per inch (CPI) is standard. Other barcode symbologies including Code 128, I 2 of 5, 2D DataMatrix and QR Code. |

| Label Copy | Printed copy may include block type, stylized type, logos or other designs. Black copy is produced photographically. Colors other than black are screen printed. |

| Colors | Choose black only or one of our standard colors (red, blue, green, dark blue, orange, purple or yellow) for block style type, stylized type, logos or other designs. Due to the contrast needed for barcode scanner, all barcodes are black. Color samples available upon request. |

| Standard Adhesive | Pressure-sensitive acrylic adhesive |

| Sizes | 63mm x 30mm; 51mm x 25mm; 38mm x 19mm; 63mm x 19mm; 38mm x 13mm; 44mm x 13mm; 51mm x 16mm; 51mm x 19mm |

| Holes | Optional |

| Packaging | Shipped in “work-out- of” cartons for convenient application. Both cartons and trays clearly marked to indicate serial numbers of contents. Pressure-sensitive adhesive orders shipped with cleaner and application instructions. |

| Shipment | 5-8 business days |

Applications

| Asset Tracking | Inventory Management | Returnable Containers |

| Audio Equipment | OEM Product Identification | School Equipment |

| Bins | Pallets | Warehouse |

| Computers | Product Branding | Work-In-Process |

| Hospital Equipment | Racks |

-

Chemical Testing

-

Destructive Testing

-

Abrasion Testing

Chemical Test Data

| Characteristics | Test Conditions | Effect |

| Water/humidity | no effect | |

| Salt spray | 5% at 35°C, 700 hours | no effect |

| Ammonium hydroxide | 2 hours at 1% and 5% | Slight dulling of image, affects overall readability |

| Ethyl alcohol | no effect | |

| Ethyl acetate | 24 hours | no effect |

| Ferric chloride | 10%, 16 hours | no effect |

| Heptane | 72 hours | no effect |

| Hydrocarbon fluid | no effect | |

| JP-4 Fuel | no effect | |

| Kerosene | no effect | |

| Methyl Ethyl Ketone | no effect | |

| Nitric acid | 1%, 40 hours | no effect |

| Phosphoric acid | 1%, 40 hours | no effect |

| Skydrol | no effect | |

| Sodium hydroxide | affects overall readability | |

| Sulfuric acid | 10%, 24 hours | no effect |

| Turbine and jet fuel (MIL-L 5161C) | (MIL-L 5161C) | no effect |

| Tetra Sodium Pyrophosphate | 1%, 40 hours | no effect |

| Trisodium Phosphate | no effect |

Destructive Test Data

A label with an intensified image was tested in a weatherometer, 20 years equivalent; reduced overall readability after these thresholds

Abrasion Test Summary