Project Description

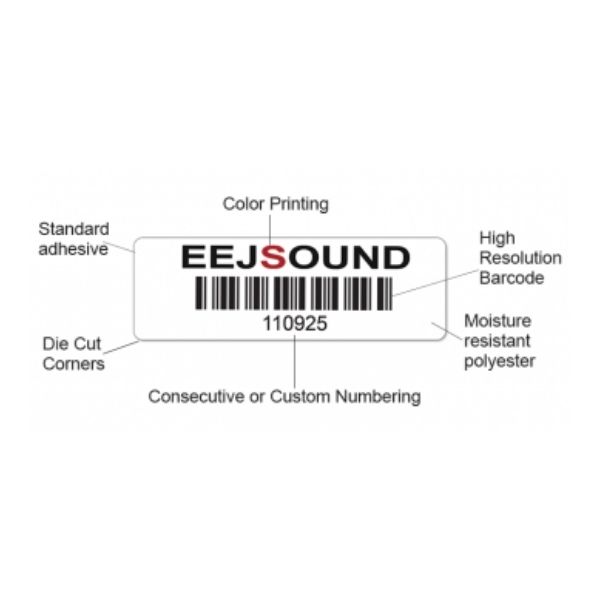

This top-of-the-line polyester label features our thickest polyester combined with a .0035″ thick adhesive.

Digital printing ensures barcode readability as well as crisp, clean company logos while subsurface printing protects the logos, copy and bar code against extreme solvents, caustics, acids and moderate abrasion.

Subsurface printing protects against extreme solvents, caustics, acids and mild abrasion while eliminating need for a laminate

Digital printing process ensures bar code readability as well as crisp, clean company logos

Custom colors available at no additional charge

Durable .003″ thick polyester material easily conforms to uneven or radius surface

.0035″ thick, pressure-sensitive adhesive for low-surface energy materials

Specification Data

| Material | .003″ thick white or silver polyester |

| Bar Code & Serialization | Serialized/unserialized numbers and bar code with human-readable numbers |

| Label Copy | The label copy may include block type, stylized type, logos or other designs |

| Colors | Standard colors include black, red, yellow, green, orange, purple, dark blue or blue. Custom spot colors are also available at no additional charge. Due to contrast needed for the bar code scanner, all bar codes are black. |

| Standard Adhesive | .0035″ adhesive with excellent durability, particularly suited for a wide range of polyolefin and other low-surface energy materials (powder paints, etc.) |

| Sizes | 51mm x 25mm; 51mm x 16mm; 32mm x 13mm; 38mm x 19mm; 51mm x 19mm; 44mm x 13mm |

| Packaging | Produced and shipped in roll form. Strip form is optional. Cleaning solution is provided to assist in applying to a clean surface. Cartons are clearly marked to indicate serial numbers of labels. |

| Shipment | 6 business days |

| Asset Tracking | OEM Product Identification | Returnable Containers |

| Audio Equipment | Office Equipment | School Equipment |

| Computers | Pallets | Security |

| Hospital Equipment | Plastic Bins | Tablets |

| Inventory Management | Plastic Totes | Tool Tracking |

| IT Assets | Product Branding | Totes |

| Laptops | Racks | Work-In-Process |

| Monitors |

-

Chemical Testing

-

Temperature Testing

-

Barcode Readibility Testing

-

Abrasion Testing

Chemical Test Data

Labels were applied to a clean glass substrate and submerged in the following chemicals for 6 hours. A 180-degree peel test was performed on each label to measure peel strength and a percentage peel strength change was calculated based on a sample left in standard room temperature dry conditions.

Chemical resistance of adhesive

| Water | Glass Cleaner |

Bathroom Cleaner |

Isopropyl Alcohol |

Acetone | NaOH pH 12 |

HN03 pH 12 |

HCI pH 12 |

Brake fluid |

Diesel fuel |

|

| Peel Strength (Control) | 9.1 | 9.1 | 9.1 | 9.1 | 9.1 | 9.1 | 9.1 | 9.1 | 9.1 | 9.1 |

| BC grade loss after chemical exposure | None | None | None | None | None | None | None | None | None | None |

Temperature Test Data

Labels were applied to a clean glass substrate and heated to the temperatures listed below for 1 hour. Peel tests were performed to compare change in adhesive strength and bar codes were graded before and after testing to measure image degradation severity.

Adhesive strength change after heat exposure

| 40° C | 100° C | 150° C | 200° C | |

| Peel Strength (Control) | 9.1 | 9.1 | 9.1 | 9.1 |

| Actual Peel Strength (lb/in) | 8.1 | 8.1 | 8.2 | 3.4 |

Barcode Readability Test Data

Barcode grade loss after heat exposure

| 40° C for 1 hour | 100° C for 1 hour | 150° C for 1 hour | 200° C for 1 hour |

| 0 | 2 | 2 | no read |

Abrasion Test Summary

Labels survived more than 6,000 revolutions on Taber Abrader using Calibrase H18 wheel with 1000g weight and remained readable with a bar code reader.