Project Description

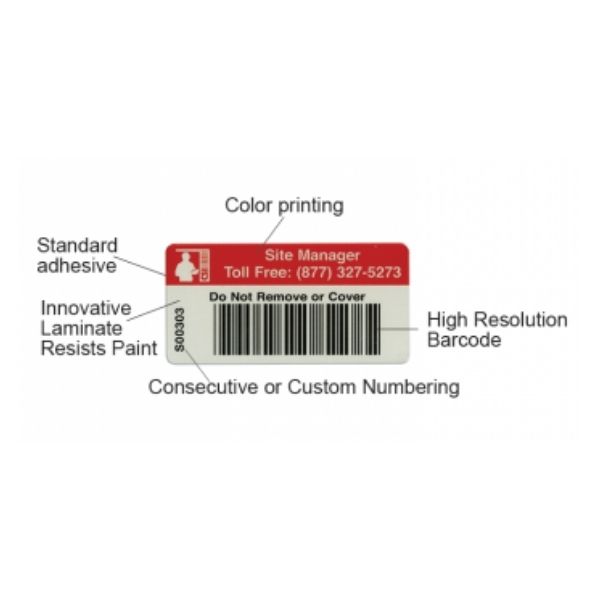

Idtracon’s Paint-Resist Metal Barcode Nameplates feature a special fluoropolymer laminate that resists 10-12 paint applications, grease, even graffiti, and can withstand temperatures up to 175°C.

After painting simply pick off the dried paint and leave a clean, easy-to-scan metal barcode nameplate – a great product for work-inprocess.

Color logos or designs available in standard colors – black, red, yellow, green or blue

Fluoropolymer laminate designed to resist up to 12 paintings and withstand continuous temperatures up to 175°C

Anodizing process and fluoropolymer laminate protects black copy, logos, and bar codes from chemicals, abrasion and high temperatures

Adhesives specially matched to surface for maximum adhesion or optional holes available for mechanical fasteners

Specifications Data

| Material | .008” thick matte anodized aluminum is standard. Optional thicknesses include: .012”, .020”, .032”, and .063”. |

| Barcode & Serialization | All alphanumeric barcodes are photo imaged with a human-readable equivalent. Guaranteed no skips in sequence. Code 39 with 2.7 to 9.4 characters per inch (CPI) is standard. Other barcode symbologies including Code 128, I 2 of 5, 2D DataMatrix and QR Code. |

| Label Copy | Printed copy may include block type, stylized type, logos or other designs. Black copy is produced photographically. Colors other than black are screen printed. |

| Colors | Choose black only or one of our standard colors (red, blue, green, purple, orange, dark blue or yellow) for block style type, stylized type, logos or other designs. Due to the contrast needed for the barcode scanner, all barcodes are black. Color samples available upon request. |

| Standard Adhesive | Pressure-sensitive acrylic adhesive; excellent bond to unpainted metal surfaces such as aluminum and stainless steel as well as glass surfaces. Will withstand temperatures from -40°C to 204°C (intermittent). Shelf life of 24 months when stored at 22°C and 50% relative humidity. |

| Sizes | Various sizes available |

| Holes | 51mm x 16mm; 51mm x 25mm; 63mm x19mm |

| Packaging | Shipped on convenient rolls shipped in “work-out-of” cartons for convenient application. Each carton consists of one or more plastic trays containing 250 sequentially packed nameplates (can vary with metal thickness). Both cartons and trays are clearly marked to indicate serial numbers of contents. Pressure-sensitive adhesive orders are shipped with a roller, cleaner, and application instructions. with scrap matrix removed for ease of removal. Cartons are clearly marked to indicate serial numbers of labels. |

| Shipment | 7-8 business days |

Asset Tracking

Work-In-Process

-

Chemical Testing

-

Temperature Testing

-

DestructiveTesting

-

Abrasion Testing

Chemical Test Data

This rating measures effect on labels after being exposed to chemicals listed below for a 2 hour soak and a 48-hour soak.

| Characteristics | Test conditions | Effect |

| Water/Humidity | ||

| Salt spray | 5% at 95°F, 700 hours | no effect |

| Ammonium hydroxide | 2 hours at 1% and 5% | slight dulling of image, affects overall readability |

| Ethyl alcohol | no effect | |

| ethyl acetate | 24 hours | no effect |

| Ferric chloride | 72 hours | no effect |

| Heptane | 72 hours | no effect |

| Hydrocarbon fluid | no effect | |

| JP-4 fuel | no effect | |

| Kerosene | no effect | |

| Methyl ethyl ketone | no effect | |

| Nitric acid | 1%, 40 hours | no effect |

| Phosphoric acid | 1%, 40 hours | no effect |

| Skydrol | no effect | |

| Sodium hydroxide | affects overall readability | |

| Turbine and jet fuel (MIL-L 5161C) | (MIL-L 5161C) | no effect |

| Tetrasodium pyrophosphate | 1%, 40 hours | no effect |

| trisodium phosphate | no effect |

Temperature Test Data

Tamper-Evident Labels are able to withstand intermittent heat exposure to 93°C and still leave the “VOID” pattern upon removal after label is allowed to cool to room temperature.

| (Image intensified) | 265 hours at 260°C, 90 hours at 315°C, 60 hours at 370°C | Reduced overall readability after these thresholds |

| UV Exposure (image intensified) | Weatherometer, 20 years equivalent | Reduced overall readability after these thresholds |

Destructive Test Data

| Image intensified | Plates brushed for 7000 cycles with stiff nylon wheel (C-17) at a 1000 gm (16 ox.) load | Reduced overall readability after these thresholds |

Abrasion Test Data

| Image intensified | Plates brushed for 7,000 cycles with stiff nylon wheel (C-17) at a 1,000 gm (16 ox.) load | Reduced overall readability after these thresholds |