Project Description

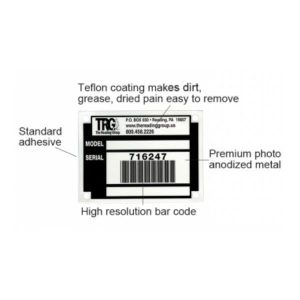

Dirt, grease, grime, even dried paint easily clean off this revolutionary nameplate due to its durable Teflon® coating.Once clean, you get a fast, accurate barcode reading to track assets, fugitive emissions or work-in-process. The Teflon® coating also resists incidental or intermittent contact with strong acids and caustics, as well as temperatures up to 260°C.

Dirt, grease or dried paint is easily removed

Teflon® coating also provides protection against long-term exposure to weather, extreme heat or cold, UV rays, and fluctuations in temperature

Photographically reproduced black copy, logos, and bar codes ensure accurate and reliable reads

Adhesives specially matched to surface for maximum adhesion or optional holes available for mechanical fasteners

Specifications Data

| Material | .012” thick anodized aluminum is standard. Optional thicknesses include .020”, .032”, and .063”. The Teflon® coating is a fluoropolymer, which is approximately .001” to .0015” thick. |

| Serialization | All alphanumeric barcodes are photo imaged with a human-readable equivalent. Guaranteed no skips in sequence. Code 39 with 2.7 to 9.4 characters per inch (CPI) is standard. Other bar code symbologies including 128, I 2 of 5, 2D DataMatrix and QR Code. |

| Label Copy | The printed label copy may include block type, stylized type, logos, and other designs. All copy is produced photographically. |

| Colors | Available in black only |

| Standard Adhesive | Pressure-sensitive acrylic adhesive |

| Sizes | 51mm x 16mm; 63mm x 19mm; 51mm x 25mm |

| Holes | Optional |

| Packaging | Shipped in “work-out-of” cartons for convenient application. Each carton consists of one or more trays containing sequentially packed nameplates (nameplates may not always have a number and a quantity packaged can vary with metal thickness). Both cartons and trays are clearly marked to indicate serial numbers of contents. Pressure-sensitive adhesive orders are shipped with a roller, cleaner, and application instructions. Roller is recommended when applying nameplates. |

| Shipment | 20-25 business days |

Asset Tracking

OEM Product Identification

-

DestructiveTesting

-

Barcode Readibility Testing

Destructive Test Data

Test performed with Taber Abrader set at 500g per wheel, with Calibrase CS-17 wheels. Resists abrasion up to 7000 revolutions before wear-through on the Teflon® coating or anodized surface occurs.

Barcode Readability Test Data

| Chemical | Result |

| Glass cleaner with ammonia | No effect |

| DI water | No effect |

| Isopropyl alcohol | No effect |

| Bathroom cleaner | No effect |

| Acetone | No effect |

| Brake fluid | No effect |

| Diesel fuel | No effect |

| Caustic soda | No effect |

| Nitric acid | No effect |

| Hydrochloric acid | No effect |