Project Description

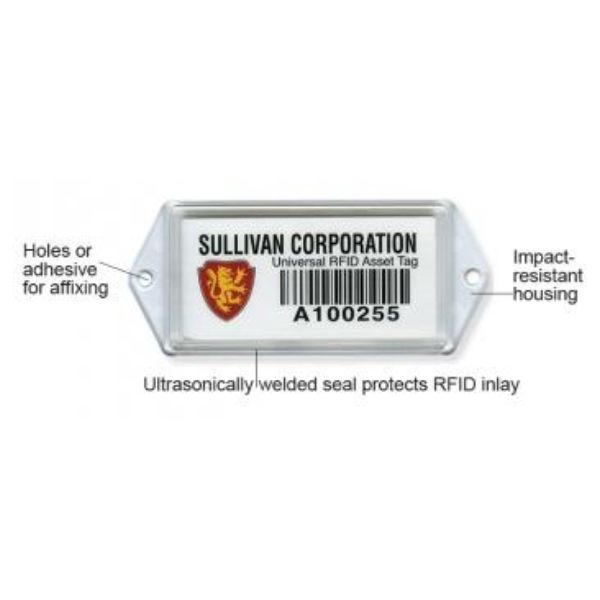

Impact-resistant housing combined with an ultrasonically welded seal protects the subsurface printed label and RFID inlay from harsh environments including harmful UV rays. Affixing methods include mechanical fasteners (standard) and/or adhesive (optional).

This revolutionary product line features surface-independent tags with a patented inlay designed to obtain excellent read ranges regardless of the surface – metal, plastic, or even wood. Custom programming matches the printed bar code information on the label allowing you the option of using both tracking technologies. No other RFID tags available offer these features!

Patented inlay design obtains excellent read range regardless of surface – metal, plastic, even wood

Impact-resistant housing protects RFID inlay from harmful UV rays

Ultrasonically welded seal protects RFID inlay from caustics/acids

Affixing methods include mechanical fasteners (standard) and/or adhesive (optional)

Specifications Data

Universal hard tag product information

| Material | .002″ thick polyester; .20″ total product thickness |

| Serialization | Barcode and human-readable equivalent is digitally printed – providing excellent clarity and easy scanning. Code 39 is the standard symbology with a range of 2.7 to 9.4 CPI (characters per inch). Optional linear and 2D symbologies available. Although this product is primarily marketed as a bar code product, we can produce it with human-readable numbers only or unserialized. |

| Label Copy | The label copy may include block type, stylized type, logos or other designs |

| Colors | Standard colors include black, red, yellow, green, dark blue, orange, purple or blue. Custom spot colors are also available at no additional charge. Due to contrast needed for the bar code scanner, all bar codes are black. |

| Standard Adhesive | High-performance adhesive |

| Frequency Range | Custom-designed UHF inlay uses Alien Higgs 3 chip optimized for use at 915 MHz. (UHF, Class I Gen 2) |

| Sizes | 105mm x 45mm |

| Packaging | Shipped in “work-out-of” cartons for convenient application. |

| Shipment | 20 business days |

Asset Tracking

Inventory Management

Logistics

Work-In-Process

-

Chemical Testing

-

Temperature Testing

-

Read Range Testing

Chemical Test Summary

In all cases, after 3 weeks soaking in these chemicals, all the tags and labels responded properly when interrogated with a handheld RFID reader, and all the bar codes except those soaked in acetone were readable with a standard bar code reader. NOTE: Samples tested with adhesive.

Chemical Test Data

| Length of immersion |

Water | Glass cleaner | Bathroom Cleaner pH 10.0 | Isop. Alcohol 99% | Acetone 1005 | NaOH pH 12.0 | HCI pH 1.0 | Brake Fluid |

| 2 hours | NE | NE | NE | NE | Surface of housing slightly cloudy | NE | NE | NE |

| 24 hours | NE | NE | NE | NE | Plastic housing softened, but RFID tag still readable | NE | NE | NE |

| 1 Week | NE | NE | NE | P.S. adhesive softened | Plastic housing brittle, opaque, but RFID tags still readable | NE | NE | NE |

| 3 Week | NE | NE | NE | P.S. adhesive softened | Plastic housing softened, but RFID tag still readable | NE | NE | NE |

Heat Testing - Product withstood temperatures up to 115°C for short term (10 minute) periods. They will withstand temperatures up to 71°C for extended periods (tested for six hours with no degradation). The tests demonstrated that when the transponder was not readable at temperatures above 85°C, but resumed function when temperatures were once again reduced below 85°C.

Cold Testing - Tags were tested outdoors at 0°C and were readable, but read distance was reduced to half of the read distance observed at 15°C.

Read Range Test Summary

In many cases the tags read intermittently for longer distances than those indicated, however, the results reported below were for continuously responding reads.

Read Range Test Data

| Device used | Test results (all at 30 dBm) | |||

| Handheld convergence CS-101 | Metal | Plastic | Cardboard | Wood |

| Universal RFID Hard Tag | 3 metres | 1.5 metres | 1.5 metres | 1.5 metres |